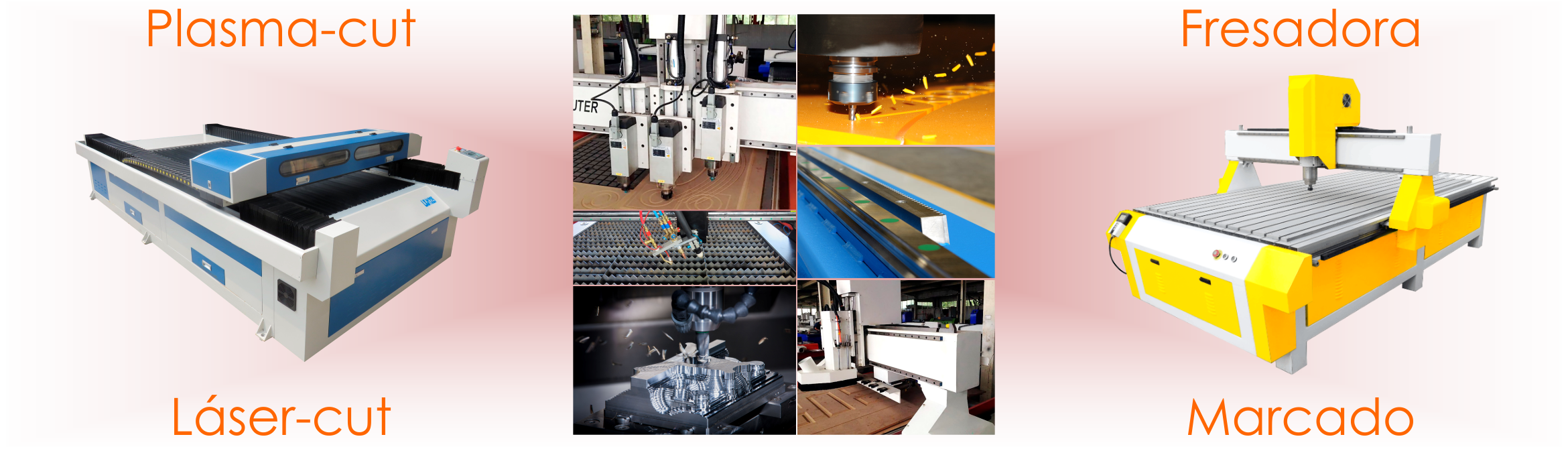

Plasma cutting machine is designed for cutting of materials by means of a special device, which converts gas into a plasma jet. As a result, the plasma cutting machine can perform cutting of any metals with thickness up to 200 mm with the best indicators of speed and quality of cutting.

It is used for cutting and pattern cutting of metal of any size and thickness. Besides, the plasma cutting machine can process non-ferrous metals. FTL machine is equipped with precision equipment, which allows to perform shape cutting with any precision of the most complex configuration.

Main elements of the plasma cutting machine are:

- Plasmatron that generates plasma using the gas supply system

- Computerized numerical control (CNC) – monitoring and control of the whole machine operation

- Gas burner

- Table, where the workpiece is positioned. Fixidity of the workpiece during operation is guaranteed

- Technique of the linear displacements and drive system provide the required speed and displacement precision

A distinctive feature of the qualitative plasma cutting machines, which FTL machines are, is a possibility to control and adjust the burner position as for height, integrated into the machine control system.

FTL Company offers the unique plasma cutting machines that use specialized devices to obtain a plasma jet. This development of American engineers, in conjunction with the most reliable mechanical and driven equipment, as well as control system, make the quality of processing using FTL plasma cutting machines the best one in its segment.