These machines are the assistants of the masters, which work in one of the most complex and industrialized sectors of the Spanish economy - metalworking and mechanical engineering. It is this sector, which is responsible for all those things made of metal, which we see and which we use on a daily basis all over the place. The metal working machines are very popular among such specialists. These machines include: CNC Routers, lathes, various saws, presses and so forth.

Cutting saws are especially popular with experts in various enterprises. Such saws perfectly cope with the various tasks associated with precise cutting of the segments of the metal blank part. These saws are available with various modifications and disk sizes. Each expert tries (concerning their characteristics) to chose the metal working machine for himself and his activity, as there are a lot of goods, which are made of metal, there are different kinds of equipment for various purposes. These saws are convenient to be used and afford to reliably fix the blank part on the table and make cuts not only across the blank part, but also at various angles. Manufacturers of this tool take care of the protection of workers, and supply the hardware with all kinds of protections.

Drilling tanks are the most popular metal working machines. This type of equipment produces both horizontal and vertical holes in the blank parts of metal and the holes at different angles. The quality of the mentioned holes is controlled by special computerized equipment. This equipment fits perfectly not only at the plant or factories, but also is perfectly suitable for home use and for use in small workshops. There presented different kinds of such machines from famous brands on the Spanish market.

Lathe Metal working machines. This equipment is indispensable in the engineering sector of the economy, but it is widely used and at service stations as well. This equipment can produce a variety of different parts. It is possible (especially on modern machines) to produce the same operations: drilling, grinding, polishing and so forth.

If you intend to open your own workshop, our experts will be happy to give you advice and help you to choose the maximum effective set of metal working machines, which will suit every budget.

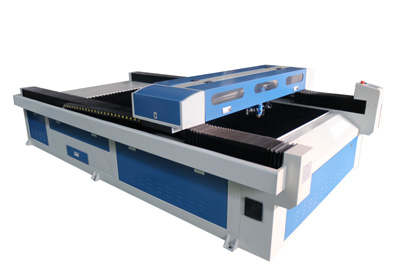

On enterprises, which keep up with the times the Laser machine is popular equipment. This machine is widely used for engraving of various materials, cutting and with other purposes. These machines are supplied with a pre-defined unit of numerical control (CNC equipment). We will try to introduce you briefly with these types of machines. Our company supplies a large enough range of such products. The equipment supplied by us can be used in various enterprises from small shops to large factories. Our experts will help you to choose equipment according to your requirements and budget.

Advantages

Laser machines are multifunctional devices. This equipment is ideal for engraving different materials. Among the materials they could engrave: acrylic, metal, leather, rubber blank parts, wood, etc. The main advantages of these machines are:

- The Laser machine can easily handle even fragile materials. The laser is not in contact with the blank part and has no vibration. Accordingly, there is no need for fixing the blank part on the working surface of the table.

- Laser engraving of the rubber. In the equipment market only laser equipment can handle the rubber blank parts.

- Speed of work with blank parts. Laser cutting machines can handle quite a large number of blank parts in a short time, which significantly increases the productive efficiency of your company.

Laser machines are not tied to a specific profile of the enterprise and can be used both by as a small furniture shops and large enterprises.

Laser machine format and its application

The dimensions of the target and productive capacity depend on the size of the working surface of the machine. It should be clearly understood what you are going to produce on it and what will be the size of the blank part you are going to dip and placed on the working surface of the machine table.

There are several formats of Laser machines:

- Small scale. The working area of these machines is 300х420 mm. These machines are ideal for promotional items and engraving of small surfaces, such as notice plates, etc.

- Medium format. These machines have the dimensions of the working area up to 1300х1600 mm.

- Heavy- duty. The working area of these machines is 1300х2500 mm. They are used mostly by big enterprises and workshops with high performance to work blank parts.

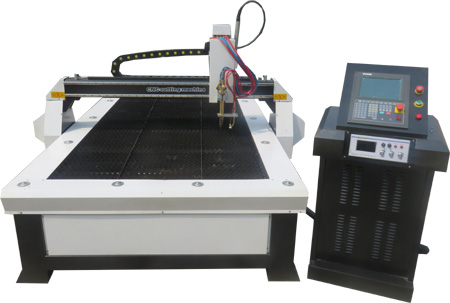

Nowadays there exist equipment to work with metal, but one of the most popular is a machine for plasma cutting of metal. This equipment enables the operator to cut out the metal of different alloys and thicknesses accurately and quickly. This equipment is widely used in various industrial activities, both by the largest enterprises and small factories and shops. But progress does not pass by this equipment, and CNC (computer numerical control) gets the job done with this machine not only fast but of extremely high quality.

The construction of plasma cutting machine

Plasma cutting machine tools with pre-block of CNC are high-performance machines, which are automated as much as possible with high performance.

The features of this construction are the following:

- The most important element of the construction of the machine is a plasmatron, with a continuous gas feeding system.

- The next element is the height of the burner control system.

- Table for the location of blank part.

- Control system (CNC).

Based on the needs of the enterprise this machine can be equipped with one or two burners.

Types of plasma cutting machines

Big enterprises and factories often choose to use stationary plasma cutting systems, as they have at least a large area of the development of the blank part. Also there exist portable plasma cutting machines with numerical control. Stationary CNC plasma cutting machines in their turn are divided into:

• Portable machines.

• Articulated machines.

• Cantilever machines.

Articulated machines allow you to work only in the vertical plane.

Features and disadvantages of plasma cutting machines

The apparent advantage of this type of equipment is incredible precision while cutting the metal blank part. CNC allows you to perform this operation up to the hundredths of a millimeter with full control of the machine gun. This feature allows you to completely disable the probability of deviation from the path of movement. The ends of the parts are absolutely smooth. Security while working on the machine, the experts are far from the burner zone. A definite plus of working on such a machine is the lack of vibration.

There are almost no deficiencies in these machines, only the thickness of the blank part and alloys. Plasma machine cannot work with metals with the thickness more than 10 cm. Also this equipment cannot cut such metals as titanium.