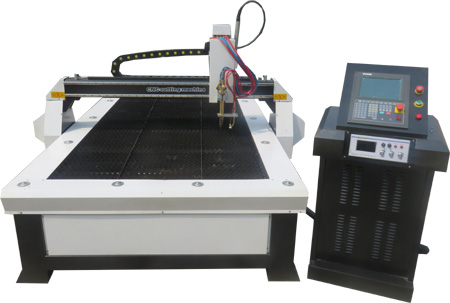

Nowadays there exist equipment to work with metal, but one of the most popular is a machine for plasma cutting of metal. This equipment enables the operator to cut out the metal of different alloys and thicknesses accurately and quickly. This equipment is widely used in various industrial activities, both by the largest enterprises and small factories and shops. But progress does not pass by this equipment, and CNC (computer numerical control) gets the job done with this machine not only fast but of extremely high quality.

The construction of plasma cutting machine

Plasma cutting machine tools with pre-block of CNC are high-performance machines, which are automated as much as possible with high performance.

The features of this construction are the following:

- The most important element of the construction of the machine is a plasmatron, with a continuous gas feeding system.

- The next element is the height of the burner control system.

- Table for the location of blank part.

- Control system (CNC).

Based on the needs of the enterprise this machine can be equipped with one or two burners.

Types of plasma cutting machines

Big enterprises and factories often choose to use stationary plasma cutting systems, as they have at least a large area of the development of the blank part. Also there exist portable plasma cutting machines with numerical control. Stationary CNC plasma cutting machines in their turn are divided into:

• Portable machines.

• Articulated machines.

• Cantilever machines.

Articulated machines allow you to work only in the vertical plane.

Features and disadvantages of plasma cutting machines

The apparent advantage of this type of equipment is incredible precision while cutting the metal blank part. CNC allows you to perform this operation up to the hundredths of a millimeter with full control of the machine gun. This feature allows you to completely disable the probability of deviation from the path of movement. The ends of the parts are absolutely smooth. Security while working on the machine, the experts are far from the burner zone. A definite plus of working on such a machine is the lack of vibration.

There are almost no deficiencies in these machines, only the thickness of the blank part and alloys. Plasma machine cannot work with metals with the thickness more than 10 cm. Also this equipment cannot cut such metals as titanium.